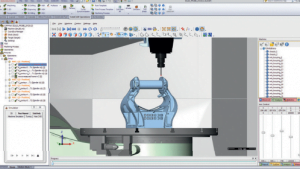

Who Can Use: Engineers, Technical Staff, Hobbyists, CNC operators and Job seekers. You can save up to 80% with iMachining toolpaths developed exclusively by Solidcam software. If you have a machine without such functions, users can input the part location inside SolidCAM and the G-code will handle all of the transformations for each rotation. When you watch the training videos, you will be able to learn CNC working logic, M, G codes, 2D and 3D design, 2½ axis milling, 3 axis milling, 4 and 5 axis milling, iMachining features with industrial applications. For controllers with advanced plane rotation or coordinate rotation functions, SolidCAM’s post processors are built to use these internal CNC functions. With this training set, you can turn your dreams into reality. The feature of our training set is that it does not only mention what the commands are for, and all subjects are reinforced with various industry applications where all commands are used. It integrates with other significant CAD and CAM solutions such as SOLIDWORKS and Autodesk Inventor. With the help of this training set, you can be an advanced Solidcam user starting from scratch. This software, which is used by many small and medium sized companies, works integrated with the Solidworks software, which is the most used in the design world. Solidcam software has the easiest interface and is the easiest to learn software in the world. With the single-window integration, all machining operations can be defined and verified without leaving the parametric CAD assembly environment you're used to.

SolidCAM is the leading Integrated CAM software which runs directly inside SOLIDWORKS and Autodesk Inventor, with seamless integration and full tool path associativity.

0 kommentar(er)

0 kommentar(er)